#sustainable pump motors

Explore tagged Tumblr posts

Text

Key Applications of an IoT-Based Pump Monitoring System: Driving Sustainability with ePropelled Motors

Industries worldwide are integrating Internet of Things IoT) technology into pump monitoring systems to enhance efficiency and sustainability. Pumps, essential for industries like water treatment and oil and gas, are now smarter and more efficient with IoT integration. At ePropelled, we lead this transformation with sustainable motors that complement IoT-based monitoring systems.

Understanding IoT-Based Pump Monitoring Systems An IoT-based pump monitoring system uses sensors and analytics to monitor parameters like flow rate, pressure, vibration, temperature, and energy use. Operators gain real-time insights via cloud platforms, enabling predictive maintenance, energy efficiency, and enhanced reliability—all critical for achieving sustainability goals.

Key Applications of IoT-Based Pump Monitoring Systems

Water and Wastewater Management Efficient water management is vital for addressing global challenges. IoT-enabled monitoring ensures pumps in water distribution and wastewater plants operate optimally, reducing energy waste, detecting leaks, and preventing breakdowns. ePropelled’s motors amplify these benefits by cutting power consumption and lowering carbon footprints.

Oil and Gas Industry In extreme conditions, inefficiencies in pump systems can lead to financial and environmental costs. IoT monitoring tracks performance metrics, detecting issues early. With ePropelled’s sustainable motors, operators ensure safe, eco-friendly operations.

Agriculture and Irrigation IoT-enabled monitoring delivers precise water usage, conserving resources and reducing waste. ePropelled’s energy-efficient motors lower operational costs and support sustainable farming.

HVAC Systems IoT-based monitoring optimizes pumps in heating, ventilation, and air conditioning systems. ePropelled’s motors align with green initiatives by improving energy efficiency.

Renewable Energy Systems IoT systems optimize pumps in solar and wind energy setups, enhancing efficiency and minimizing environmental impact. ePropelled motors ensure peak performance and sustainability.

The ePropelled Advantage Our advanced motors reduce energy consumption, extend equipment lifespan, and support global sustainability goals. Combined with IoT-based monitoring, they: · Reduce downtime via predictive maintenance · Minimize energy usage and costs · Prevent wear and tear · Lower carbon emissions

Conclusion IoT-based pump monitoring systems, paired with ePropelled’s motors, deliver smarter, greener operations. Connect with us to revolutionize your pump systems and drive a sustainable future.

#pool pump and filter#electric water pump#submersible water pump#pool pump motor#swimming pool pump motor#swimming pool pump and filter#swimming pool filtration pump#pool pump#sustainable pump motors

0 notes

Text

1940 10 20 HMS Hotspur rams submarine Lafole - Chris French

18:30hrs, 20th October 1940. Royal Navy H-Class destroyer HMS Hotspur rams the Italian submarine Lafolè in the western Mediterranean. RN ships had been engaged in seven hours of cat-and-mouse with the submarine, depth charges having damaged electric motors and pumps on Lafolè, bending the propeller shafts and causing flooding. Ultimately, the submarine could not sustain a dive and surfaced repeatedly, the final time being directly in front of HMS Hotspur. The destroyer going full speed rammed the submarine in the area of the conning tower and it sank soon after. 9 survivors were picked up. Hotspur underwent temporary repairs to her bow at Gibraltar with permanent repairs made later at Malta, completed by February 1941.

37 notes

·

View notes

Text

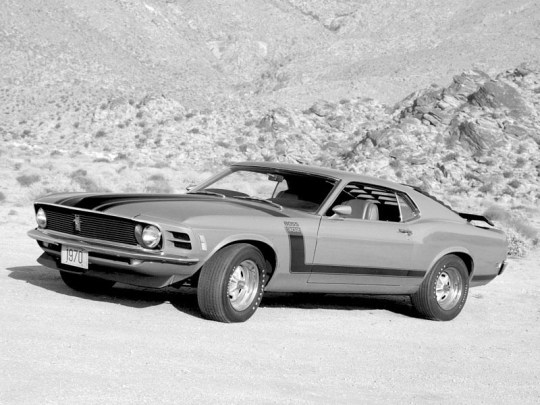

FORD MUSTANG BOSS 302

BOSS-A-NOVA!

They called it The Boss and for two short years it ruled the muscle car scene in the US, establishing itself as one of the greatest road and race cars of the era. Now, it’s one of the most collectible.

In 1960s US street lingo, if something was ‘boss’ it was cool, tough, the best. And the 1969 Boss 302 Mustang wore its badge with pride. It launched just four and a half years after the first Mustang was revealed to critical acclaim and record sales. Yearly updates to keep Mustang fresh in the face of tough new challengers from General Motors and Chrysler (particularly the Camaro) resulted in the once lean and pretty ’Stang muscling up, both in body shape and under-bonnet brawn, and the 1969-70 Boss models were the zenith of Mustang styling.

Thereafter, Mustangs became increasingly bloated and anaemic as the 1970s fuel crisis and stricter pollution laws cut horsepower and stylists lost their way; the rippling flanks and thrusting nose of the late 60s/early 70s cars gave way to boxy, bland designs. That early look would not be recaptured until 2005, when new Mustangs were given retro styling.

The Boss 302 was launched at the same time as its big-block brother, the Boss 429. Both were positioned as competition specials; Ford wanted to homologate its 302-cuber for Trans-Am and the 429ci monster for NASCAR. In fact, Ford went wild with engines between 1969-70, offering nine V8s – the ‘economy’ 302, 351 Windsor, 351 Cleveland, 390, 428 Cobra Jet, 428 Super Cobra Jet, 429 ‘wedge’, Boss 302 and Boss 429.

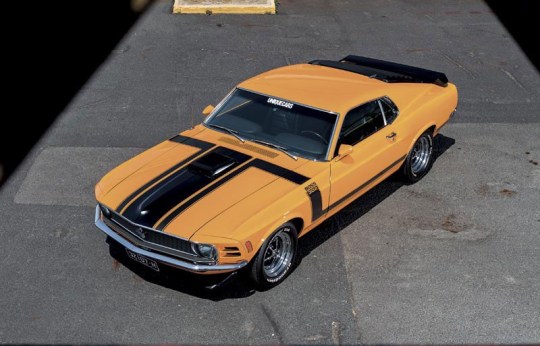

For the Boss 302, Ford’s high-compression 302ci small-block V8 was beefed up with four-bolt main bearing caps and redesigned ‘Cleveland’ cylinder heads with bigger inlet and exhaust valves, and ports that allowed the engine to breathe more efficiently.

These ‘semi-hemi’ heads were based on the Ford 427ci racing engine’s combustion chambers, and a balanced forged steel crankshaft and forged steel conrods allowed the engine to handle high rpms for sustained periods. A single 780cfm four-barrel Holley carburettor sat atop a high-rise aluminium inlet manifold, while a dual-point distributor, high-pressure oil pump, windage tray and screw-in welch plugs were further indications of its competition intent.

A rev limiter was fitted, progressively cutting spark from 5800rpm to 6150, but it was easily bypassed and the Boss 302 could reportedly keep making power up to 8000rpm with minor mods. In the muscle car marketing war, Ford claimed a peak horsepower figure of 290bhp at 5800rpm (the same as the Camaro Z/28), but that was extremely conservative.

Two four-speed manual Top Loader transmissions were available: a wide-ratio ’box with Hurst shifter more suited to street and strip use, and a close-ratio unit for racing. Adding to the race or road options list were four diffs: the stock 3.5:1 nine-inch, Traction-Lok 3.5:1 and 3.91:1 and the No-Spin 4.30:1 built by Detroit Automotive. Axles and diff centres were also strengthened to take the loads.

Suspension was also race-inspired with heavy-duty springs, shocks and sway bar up front, and Hotchkiss-style rear suspension with heavy-duty leaf springs, sway bar and staggered shock absorbers. The left-hand shock absorber was bolted behind the axle and the right in front, to reduce axle tramp under acceleration. Amazingly for such a high-performance car, braking was still only discs and drums with power assistance.

Ironically, the Boss 302’s sexy shape was styled by former General Motors designer Larry Shinoda, who is often credited with coming up with the Boss moniker. When asked what he was working on, he replied, "The boss’s car", a reference to new Ford president ‘Bunkie’ Knudson, who was also ex-GM and had recruited Shinoda to Ford.

While the wheelbase remained unchanged at 2740mm, the ’69 Mustang was 96.5mm longer overall to accommodate all the V8s offered, although the big-blocks still had to be shoe-horned under the bonnet. Shinoda’s ’69 Boss 302 was also one of the first production cars to offer an optional front air dam and adjustable rear wing, and his use of high-contrast black panels, rear window SportsSlats, and go-faster stripes made the Boss a real attention-grabber. The ’69 was also the only quad-headlight Mustang, a feature that was dropped for 1970 models.

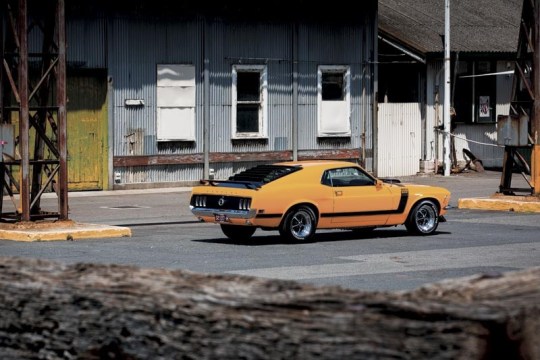

In 1970, American Hot Rod magazine dubbed the 1970 Boss 302 as "definitely the best handling car Ford has ever built", while the conservative Consumer Guide called it "uncomfortable at any speed over anything but the smoothest surface". Unique Cars resident Mustang maniac, ‘Uncle’ Phil Walker, never read the Consumer Guide review, but even if he had it wouldn’t have stopped him buying the immaculate 1970 Grabber Orange Boss 302 you see here.

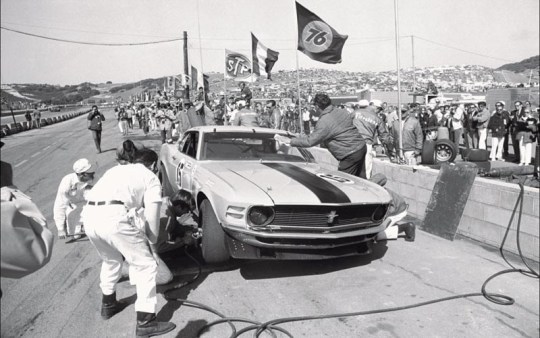

Phil already has his beloved 1966 Shelby GT350H, but the Boss 302 really got his Mustang juices percolating. And he wasn’t alone, because the first Boss he saw, some 43 years ago, is still one of Australia’s most iconic race cars: Allan Moffat’s Trans-Am racer. Phil remembers it clearly.

"I saw Moff race it Calder and I was inspired to own one," Phil recalls. "It was the most aggressive-looking car; its stance was something you had to see to believe. It looked like it was doing a million miles per hour when it was parked.

"My Boss was originally a one-owner car and I bought it from a friend of mine in California, Dave, who I also bought my Shelby GT350H from 19 years ago. Dave found it in a barn with a blown engine, but in otherwise pretty good condition.

"The lady who owned it from new didn’t realise it had a high-compression engine and had run it on standard fuel. When it blew up she just parked it.

"Dave did a nut-and-bolt restoration over two years, then put it up on his hoist. He didn’t want to sell it, but I got my way in the end – unfortunately he had the last say on the price (laughs). I didn’t even bother to test drive it; I knew it was a good car. It had 21 (new) miles on the odo when I picked it up and only 54,000 miles in total."

Since then, Phil has only put a couple of hundred miles on the car, but that’s enough for him to have bonded with it.

"I’ve only had the Boss since January and it’s growing on me. It’s different to the Shelby. It’s bigger and very low.

"The engine is incredible. Dave is one of the best engine builders in California and when he rebuilt the 302 he changed the cam spec. US camshaft technology was okay in the 60s and 70s, but if you had a big-cam muscle car they wouldn’t idle and they were terrible for driving in cities.

"A proper Boss engine can rev to 8500rpm all day and for a V8 that’s pretty serious. But they’re not renowned for low-down torque; it starts coming on from 3500rpm. My car still has a solid-lifter cam, but it pulls like a train from 1200rpm in top gear and I can drive it around at 1500rpm in top all day.

"It’s got the four-speed close-ratio Top Loader with the long first gear and with a 3.7:1 rear end it does about 55-60mph (89-97km/h) in first gear. It bloody goes!"

Phil is a fussy bugger and his cars have to look just right, so Russell Stuckey from Stuckey Tyres has ordered him a set of genuine 15 x 8 Minilites from England to replace the standard Magnum 500s.

"I want it to look like the Parnelli Jones race car, and to get the stance I want it’s going to have 275/60s on the rear and 255/60s on the front. At the moment it’s a pretty car that is tough, but I want a tough car that looks tough. And that’s all I’m going to do to it."

After his first real fang in the Boss, Phil felt that his Shelby would be half a lap in front at the end of a 10-lap sprint at Sandown, but now thinks the Boss would be quicker. We might have to put both to the acid test one day. What do you mean "no way", Phil?

It was a nervous Phil who turned up at a Melbourne storage facility in January to pick up his new Boss 302. So nervous, in fact, that he took along Unique Cars art director Ange and a sturdy tow rope – just in case.

The storage people were even more apprehensive – they had been warned about just how anal he is with his cars, as he explains: "The lady there said, ‘You must be pretty fanatical because we’ve been given strict instructions that no one is to touch the car except you’." Fortunately, the car arrived in pristine condition.

"I was pretty excited, I’d been waiting for seven weeks," Phil laughs. "I took the car cover off it, fired it up, and it drove home like a brand new car. It was as good as I thought it would be. I spent the next three hours washing it."

Sounds like our Phil.

PARNELLI AND ME

Three years ago, my mate Dave and I were invited to a Trans-Am dinner at Portland International Raceway where Dave was racing his 1970 Trans-Am Boss 302 and I was crewing for him.

When we were driving there we noticed this black Mercedes following us. When we stopped it did too and this bloke got out and said, "I noticed you guys back at the hotel. You’re going to the Trans-Am dinner aren’t you? I’m lost." It was Parnelli Jones!

I jumped in with him and when we got there I ‘invited’ myself onto Parnelli’s table, which also included Pete Brock – the guy who designed the Shelby Daytona Coupe. There was I, Mr Nobody, with all these US racing heavies, but Parnelli was a real gentleman, not up himself in any way.

The next day they had free lap time at Portland and, when I saw Parnelli there with Ford’s new ‘Parnelli Jones’ Boss 302 tribute Mustang, I asked if there was any chance of a ride and he said jump in. We did 10 laps and the guy hadn’t lost any of his ability; my eyes were getting bigger and bigger coming into the corners.

It was a great experience that I’ll never forget. – PW

IT's MINE...

Moff’s Mustang is probably the most iconic Australian racecar and after seeing it I was inspired to own a Boss Mustang. Then, about 25 years ago, I went to Pebble Beach in Monterey for the first time and saw a 1970 Grabber Orange Boss 302, which was the colour Parnelli Jones raced in Trans-Am. That day I knew I had to own a Boss. It was the car I’d always wanted after my Shelby, which was my lifelong dream car.

My Boss 302 is fully optioned, including the Shaker, extra side mirror, tacho and rear louvres, and it’s got a lot of wow factor. When you drive down the freeway, you get the thumbs-up from all sorts of different people. I think it’s the colour.

It’s closer to show standard than my Shelby. It’s got the paint marks on the tailshaft and all the little concours details, but I’m never going to show it; I’m not into that.

The 1969/70 body shape is still the best. Ford got it right then, but lost the plot after that and it’s reflected in their collectibility today. – PW

#car#cars#muscle car#american muscle#ford#FORD MUSTANG BOSS 302#ford mustang#boss 302#MUSTANG BOSS 302#mustang

163 notes

·

View notes

Text

Press release from my undergrad university about my paper :D

(artist's recreation of the texture of an active nematic liquid crystal)

Controlling the chaos of active fluids reporting by Sonia Fernandez of UCSB's The Current

Physicists at UC Santa Barbara, with colleagues at University of Michigan (UM) and The University of Chicago (UChicago), have developed design rules that take advantage of topological defects to control self-sustained chaotic flows in active fluids. This framework, for now developed as a theoretical model, provides a path for the engineering of self-powered fluids with tunable flows.

“And we can do this either at the level of one defect or at a level of many defects, which provides another way of controlling the flow dynamics,” said UCSB theoretical physicist Cristina Marchetti, a senior author of a paper that appears in the Proceedings of the National Academy of Sciences.

According to the paper, the work “establishes an additive framework to sculpt flows and manipulate active defects in both space and time, paving the way to design programmable active and living materials for transport, memory and logic.”

Active matter in general is fascinating for the ability of its constituent parts — whether they be motor proteins, bacteria, synthetic microswimmers, or humans — to collectively behave like an out-of-equilibrium material. A familiar example is a flock of starlings that move together, bending and folding in the sky like a fluid. Active fluids developed in the lab are similarly composed of individual molecular-scale units that, like the birds, consume energy and turn it into movement. Through interactions they organize in emergent structures that act in unison.

Researchers for this study, including theoretician Mark Bowick from UCSB Kavli Institute for Theoretical Physics (KITP), lead author Suraj Shankar at UM and Luca Scharrer, a UCSB College of Creative Studies physics alum, now a graduate student at UChicago, focused on an active fluid made of biomolecular proteins and filaments. In this fluid, known as an active nematic liquid crystal, the rod-like filamentary proteins tend to align with each other — the “nematic” part. The “active’’ part comes from the ability of these lined-up filaments to exert forces on their surroundings, pumping fluid and driving large-scale flows.

“This active liquid crystal is a fluid that continuously flows on its own, without any external applied force or pressure difference,” Marchetti added, thanks to local chemical reactions by so-called “motor proteins’’ that generate the energy for movement.

These flows, however, are inherently chaotic, with swirls and eddies that continuously distort the local alignment of the filaments. This creates patterns in the otherwise regular arrangement of the rod-like filaments, with strong distortions similar to the ridges in your fingerprints. The structure of these distortions is dictated by geometry and topology, earning them the label “topological defects.” The defects in turn influence the orientation and movements of the other rods around them, and the resulting flows.

“In our work we formulate design rules that dictate how particular defect structure patterns can be created, moved and even braided around each other through what we call ‘topological tweezers.’”

Defects are commonly observed in passive liquid crystals. “In the active case, an entirely new feature is observed,” added Bowick. “The defects become self-propelled, like tiny engines roaming around the fluid.” While the disturbances are localized, they move and continuously stir the entire fluid.

But rather than being bugs, these “tiny engines” can be used as features that allow for the control of active flows via the control of defect motion. The control of active defects is indeed a hot topic of experimental research, with various strategies developed to influence their generation and dynamics. Until now, however, a systematic quantification and design framework for the manipulation of defects has been missing.

“In our work we formulate design rules that dictate how particular defect structure patterns can be created, moved and even braided around each other through what we call ‘topological tweezers.’” Bowick said. This is achieved by “designing patterns of ‘activity’ in space and time,” Marchetti explained, that is “by controlling the structure and extent of the regions where chemical reactions drive fluid pumping.”

This spatial variability is achievable in experiments through light-responsive motor proteins and filaments. It allows scientists to essentially grab individual defects and move them around to design the flow that goes along with them. The researchers also demonstrate how simple activity patterns can control large collections of swirling defects that continually drive turbulent flows.

The main part of the research was carried out while Scharrer was an undergraduate student at UCSB. This demonstrates the impact of undergraduate research and the key role faculty advisors such as Sathya Guruswamy play in matching promising undergraduates with suitable research groups.

It's still early days for this work, but the scientists can see a potential array of applications and implications, for everything from biological processes to soft robotics and fluid-based logic devices. “Our work suggests how these processes can be controlled by manipulating active defects,” Bowick said

8 notes

·

View notes

Text

Top 10 Projects for BE Electrical Engineering Students

Embarking on a Bachelor of Engineering (BE) in Electrical Engineering opens up a world of innovation and creativity. One of the best ways to apply theoretical knowledge is through practical projects that not only enhance your skills but also boost your resume. Here are the top 10 projects for BE Electrical Engineering students, designed to challenge you and showcase your talents.

1. Smart Home Automation System

Overview: Develop a system that allows users to control home appliances remotely using a smartphone app or voice commands.

Key Components:

Microcontroller (Arduino or Raspberry Pi)

Wi-Fi or Bluetooth module

Sensors (temperature, motion, light)

Learning Outcome: Understand IoT concepts and the integration of hardware and software.

2. Solar Power Generation System

Overview: Create a solar panel system that converts sunlight into electricity, suitable for powering small devices or homes.

Key Components:

Solar panels

Charge controller

Inverter

Battery storage

Learning Outcome: Gain insights into renewable energy sources and energy conversion.

3. Automated Irrigation System

Overview: Design a system that automates the watering of plants based on soil moisture levels.

Key Components:

Soil moisture sensor

Water pump

Microcontroller

Relay module

Learning Outcome: Learn about sensor integration and automation in agriculture.

4. Electric Vehicle Charging Station

Overview: Build a prototype for an electric vehicle (EV) charging station that monitors and controls charging processes.

Key Components:

Power electronics (rectifier, inverter)

Microcontroller

LCD display

Safety features (fuses, circuit breakers)

Learning Outcome: Explore the fundamentals of electric vehicles and charging technologies.

5. Gesture-Controlled Robot

Overview: Develop a robot that can be controlled using hand gestures via sensors or cameras.

Key Components:

Microcontroller (Arduino)

Motors and wheels

Ultrasonic or infrared sensors

Gesture recognition module

Learning Outcome: Understand robotics, programming, and sensor technologies.

6. Power Factor Correction System

Overview: Create a system that improves the power factor in electrical circuits to enhance efficiency.

Key Components:

Capacitors

Microcontroller

Current and voltage sensors

Relay for switching

Learning Outcome: Learn about power quality and its importance in electrical systems.

7. Wireless Power Transmission

Overview: Experiment with transmitting power wirelessly over short distances.

Key Components:

Resonant inductive coupling setup

Power source

Load (LED, small motor)

Learning Outcome: Explore concepts of electromagnetic fields and energy transfer.

8. Voice-Controlled Home Assistant

Overview: Build a home assistant that can respond to voice commands to control devices or provide information.

Key Components:

Microcontroller (Raspberry Pi preferred)

Voice recognition module

Wi-Fi module

Connected devices (lights, speakers)

Learning Outcome: Gain experience in natural language processing and AI integration.

9. Traffic Light Control System Using Microcontroller

Overview: Design a smart traffic light system that optimizes traffic flow based on real-time data.

Key Components:

Microcontroller (Arduino)

LED lights

Sensors (for vehicle detection)

Timer module

Learning Outcome: Understand traffic management systems and embedded programming.

10. Data Acquisition System

Overview: Develop a system that collects and analyzes data from various sensors (temperature, humidity, etc.).

Key Components:

Microcontroller (Arduino or Raspberry Pi)

Multiple sensors

Data logging software

Display (LCD or web interface)

Learning Outcome: Learn about data collection, processing, and analysis.

Conclusion

Engaging in these projects not only enhances your practical skills but also reinforces your theoretical knowledge. Whether you aim to develop sustainable technologies, innovate in robotics, or contribute to smart cities, these projects can serve as stepping stones in your journey as an electrical engineer. Choose a project that aligns with your interests, and don’t hesitate to seek guidance from your professors and peers. Happy engineering!

4 notes

·

View notes

Text

Exploring the Future of Efficiency and Comfort: Honda Jazz Hybrid

In the world of compact cars, where efficiency meets innovation, the Honda Jazz Hybrid stands out as a beacon of modern automotive engineering. Combining Honda's renowned reliability with hybrid technology, the Jazz Hybrid offers a compelling package for eco-conscious drivers who refuse to compromise on comfort and versatility.

Honda Jazz Hybrid Specifications

The heart of the Honda Jazz Hybrid lies in its advanced hybrid powertrain. Under the hood, you'll find a responsive 1.5-litre i-VTEC engine paired seamlessly with an electric motor, delivering a harmonious blend of power and efficiency. This setup not only enhances fuel economy but also reduces emissions, making the Jazz Hybrid a responsible choice for environmentally aware consumers.

Engine Specifications:

- Engine: 1.5-litre i-VTEC 4-cylinder

- Electric Motor: Integrated Motor Assist (IMA) system

- Combined Output: Approximately 110 horsepower

The hybrid powertrain is complemented by Honda's innovative e: HEV technology, which intelligently manages the engine and electric motor for optimal efficiency in various driving conditions. This synergy ensures that whether you're navigating city streets or cruising on the highway, the Jazz Hybrid delivers a smooth and responsive performance.

User Experience: Driving the Honda Jazz Hybrid

Driving the Honda Jazz Hybrid is an experience that blends practicality with a touch of sophistication. The cabin welcomes you with a thoughtfully designed interior that maximizes space and comfort. Despite its compact exterior dimensions, the Jazz Hybrid surprises with its roomy interior, offering ample headroom and legroom for both front and rear passengers.

Interior Features:

- Magic Seats: Honda's versatile Magic Seats system allows for multiple configurations, enabling easy adaptation to accommodate various cargo shapes and sizes.

- Infotainment: The Jazz Hybrid boasts a modern infotainment system with a touchscreen display, offering connectivity options such as Apple CarPlay® and Android Auto™ integration.

The driving dynamics of the Jazz Hybrid are tuned to provide a balanced blend of agility and stability. Whether you're manoeuvring through narrow city streets or tackling curvy roads, accurate steering and quick handling provide a sense of assurance while driving. The regenerative braking system not only enhances efficiency but also contributes to a smooth braking experience, seamlessly transitioning between electric and friction braking.

Design and Technology

The Honda Jazz Hybrid's design ethos revolves around functionality and aerodynamic efficiency. Its sleek exterior lines not only enhance its visual appeal but also contribute to its fuel-saving capabilities. LED headlights and daytime running lights provide enhanced visibility, while the aerodynamically optimized body minimizes drag for improved efficiency.

Safety Features:

- Honda Sensing® Suite: Standard on most trims, Honda Sensing® includes features like Collision Mitigation Braking System™ (CMBS™), Lane Keeping Assist System (LKAS), Adaptive Cruise Control (ACC), and Road Departure Mitigation System (RDM).

- Multi-Angle Rearview Camera: Assists in parking and reversing manoeuvres, providing multiple viewing angles for enhanced awareness.

Ownership and Sustainability

Owning a Honda Jazz Hybrid extends beyond the joy of driving. It demonstrates a dedication to promoting sustainability and ethical living practices. With its hybrid powertrain, the Jazz Hybrid helps reduce your carbon footprint without compromising on performance or convenience. Honda's reputation for reliability ensures peace of mind, backed by a strong warranty and comprehensive service network.

Fuel Efficiency: The Honda Jazz Hybrid boasts impressive fuel efficiency figures, making it an ideal choice for daily commuting and long-distance journeys alike. With its hybrid powertrain, expect to achieve excellent mileage and fewer stops at the pump.

Conclusion

In conclusion, the Honda Jazz Hybrid stands as a testament to Honda's dedication to innovation and sustainability. It combines the practicality of a compact car with the efficiency of hybrid technology, offering a compelling choice for discerning drivers who prioritize both performance and environmental consciousness. Whether you're drawn to its fuel-saving capabilities, spacious interior, or advanced safety features, the Jazz Hybrid promises a driving experience that is as rewarding as it is responsible.

As the automotive industry continues to evolve, the Honda Jazz Hybrid remains a frontrunner in the realm of efficient and comfortable urban mobility. With its blend of cutting-edge technology and timeless Honda reliability, the Jazz Hybrid is poised to lead the charge towards a more sustainable future on the roads.

For those seeking a vehicle that not only meets but exceeds expectations, the Honda Jazz Hybrid emerges as a clear winner in the competitive landscape of hybrid compact cars. Embrace the future of efficient and comfortable driving with the Honda Jazz Hybrid — where innovation meets inspiration on every journey.

4 notes

·

View notes

Text

Homemade Solar Panel: Repurpose Old CDs for Energy

Do you want to join the renewable energy revolution without breaking the bank?

With just a few simple materials, you can repurpose old CDs to make a photovoltaic solar panel that can generate up to 12 volts of energy.

You'll be amazed at what you can do with a homemade solar panel - power LED bulbs, motors, and even water pumps!

So let's get started and make a difference.

Gather Materials

To make your own solar panel, you'll need some recycled materials. These include aluminum foil, PVC pipe, wood, screws, washers, cable, and used CDs. By using recycled materials for DIY projects, you can benefit from repurposing old CDs and create a sustainable and eco-friendly solar panel.

Here are some tips for building a solar panel at home:

Start by disassembling the frame and use a piece of pipe to make a support that is inclined at 45 degrees.

Then, mark the position of the CDs and drill the holes.

After that, cover the frame with aluminum foil and stick it with adhesive tape.

Add the cables and screw the plug on the rear.

Finally, place the CDs and connect them with the electrodes.

Now you have a 12-volt solar panel!

Crafting a Solar Panel

Now, let's start crafting our own solar panel using recycled materials!

To do this, we will need:

15 used CDs

A piece of PVC pipe

Aluminum foil

A piece of wood

Two screws

Two washers

A piece of cable with terminals

A frame

With these materials, we will be able to make a 12-volt solar panel that will be able to sustainably power a variety of applications.

Here's how we'll do it:

Turn the frame over and mark where the PVC pipe will go.

Heat the end of the pipe and flatten it.

Mark three holes to screw the pipe to the wood.

Secure the support by screwing the pipe to the wood.

Cover the surface with aluminum foil and secure it with transparent adhesive tape.

Attach the cables and the CDs, making sure to connect the electrodes to the aluminum foil.

Place the frame and the glass protector to complete the solar panel.

With increased solar panel efficiency, our DIY solar panel projects can be great sustainable energy solutions!

Adding the Conductive Parts

You will need to cut a 60-centimeter piece of paper into three pieces and two 40-centimeter pieces. Mark a hole for the cable to come through.

Now, with the two 40-centimeter pieces, fold them to create two conductors.

Then, with the three 60-centimeter pieces, fold them to create three conductors.

You will then use these conductors to form the conductive tracks on top of the CDs.

To secure the tracks, use a transparent adhesive tape. This will ensure that the electrodes of the positive cable make good contact with the silicon layer of the CDs.

Experiment with different conductive materials to see what has the greatest impact on the solar panel's efficiency.

Creating the right conductive tracks will help to maximize the power generated by the solar panel.

Creating the CD Matrix

Start by gluing the CDs together in the center with hot glue.

Explore alternative materials, enhance solar panel efficiency, and design a compact solar panel.

Take the time to mark the position of the CDs and carefully drill holes.

Use heat to flatten the tube and secure it with the screws.

Cut the paper into 2 x 40-centimeter pieces and 3 x 60-centimeter pieces.

Place the pieces on the wood and mark a hole for the cable.

Put aluminum foil on the frame and attach it with adhesive tape.

Screw the bracket plug from the leg to the back.

Put the screw in the center of the holes and insert the cable.

Place the electrodes on the CDs and connect it with the cable.

Secure the CDs with hot glue and add a glass protector with an aluminum frame.

Testing the Homemade Solar Panel

Connect the voltmeter to check the voltage the panel is giving you. You can see it is providing a consistent 12.5 volts.

To test it further, you can also connect a 12V light bulb to the cables and it will turn on without any issues.

The fact that this power is coming from just a homemade solar panel is amazing and can be used in a number of ways. For instance, you can power a motor, a water pump, or even light your home. You can also charge your phone with it.

Comparing with commercial solar panels, it is just as efficient and cost-effective as the store bought ones.

However, the performance of the panel can be affected by weather conditions, so it is important to keep that in mind.

Summary

You can now enjoy the benefits of renewable energy without breaking the bank with your homemade solar panel!

With 15 used CDs and a few simple materials, you can generate up to 12 volts of energy. It's an easy project that can power LED bulbs, motors, and water pumps.

The best part is that you can save around 80% on your energy bill.

So, start the project today and get ready to reap the rewards of renewable energy!

youtube

#solar#solar power#diyenergysystem#diyhomeenergy#diysolarpanel#solar panels#solar energy#solar system#Youtube

5 notes

·

View notes

Text

Zero Friction Coatings Market: Charting the Course for Enhanced Performance and Sustainable Solutions

The global zero friction coatings market size is estimated to reach USD 1,346.00 million by 2030 according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 5.6% from 2022 to 2030. Growth can be attributed to the fact that these coatings reduce friction and wear resulting in low fuel consumption and less heat generation. According to the European Automobile Manufacturers' Association, 79.1 million motor vehicles were produced across the globe in 2021 which was up by 1.3% as compared to 2020. Zero friction coatings can extend the time between component maintenance and replacement, especially for machine parts that are expensive to manufacture.

Zero Friction Coatings Market Report Highlights

In 2021, molybdenum disulfide emerged as the dominant type segment by contributing around 50% of the revenue share. This is attributed to its properties such as low coefficient of friction at high loads, electrical insulation, and wide temperature range

The automobile & transportation was the dominating end-use segment accounting for a revenue share of more than 35% in 2021 due to the rapid growth of the automotive industry across the globe

The energy end-use segment is anticipated to grow at a CAGR of 5.7% in terms of revenue by 2030, owing to the excessive wear on the drill stem assembly and the well casing during the drilling operations in the oil and gas sector

In Asia Pacific, the market is projected to witness the highest CAGR of 5.8% over the predicted years owing to the presence of car manufacturing industries in the countries such as Japan, South Korea, and China

For More Details or Sample Copy please visit link @: Zero Friction Coatings Market Report

Several applications in the automobile industry use wear-resistant plastic seals that require zero tolerance for failure and lifetime service confidence. Increasing demand for the product from the automotive industry across the globe for various applications including fuel pumps, automatic transmissions, oil pumps, braking systems, and others is expected to drive its demand over the forecast period.

Low friction coatings can be used in extreme environments comprising high pressure, temperatures, and vacuums. These coatings can provide improved service life and performance thereby eliminating the need for wet lubricants in environments that require chemicals, heat, or clean room conditions. The product containing molybdenum disulfide (MoS2) are suitable for reinforced plastics while those free from MoS2 are suitable for non-reinforced plastics.

Zero friction coatings are paint-like products containing submicron-sized particles of solid lubricants dispersed through resin blends and solvents. The product can be applied using conventional painting techniques such as dipping, spraying, or brushing. The thickness of the film has a considerable influence on the anti-corrosion properties, coefficient of friction, and service life of the product. Its thickness should be greater than the surface roughness of the mating surfaces.

ZeroFrictionCoatingsMarket #FrictionlessTechnology #CoatingInnovations #IndustrialEfficiency #ZeroFrictionSolutions #AdvancedMaterials #SurfaceCoatings #ManufacturingAdvancements #GlobalIndustryTrends #InnovativeCoatings #PerformanceOptimization #MechanicalSystems #SustainableTechnology #IndustrialApplications #FutureTech #InnovationInMaterials #EfficiencySolutions #ZeroFrictionMarket #TechnologyInnovation #EngineeringMaterials

#Zero Friction Coatings Market#Frictionless Technology#Coating Innovations#Industrial Efficiency#Zero Friction Solutions#Advanced Materials#Surface Coatings#Manufacturing Advancements#Global Industry Trends#Innovative Coatings#Performance Optimization#Mechanical Systems#Sustainable Technology#Industrial Applications#Future Tech#Innovation In Materials#Efficiency Solutions#Zero Friction Market#Technology Innovation#Engineering Materials

2 notes

·

View notes

Text

🔷️ #CentrifugalPump Installation and Commissioning Guide

The process of installing and commissioning a centrifugal pump is crucial to ensuring optimal performance and longevity. Here’s a structured approach to make sure your pump operates efficiently and reliably:

1. Pre-Installation Inspection:

1️⃣Inspect the pump and all related components for any potential damage that may have occurred during transit.

2️⃣Ensure that all required parts and accessories for installation are present.

2. Location Selection:

Choose a suitable installation location for the pump considering easy access, proper ventilation, and proximity to the fluid source.

3. Foundation Preparation:

Prepare a strong and level foundation that can support the pump and motor assembly’s weight, ensuring proper alignment with the connected piping system.

4. Piping Installation:

1️⃣Install the suction and discharge pipes with proper sizing, support, and alignment.

2️⃣Use appropriate fittings and seals to avoid any potential leaks.

5. Electrical Connection:

Connect the motor to the power source as per the manufacturer’s instructions, ensuring correct grounding and overload protection.

6. Alignment:

1️⃣Align the pump and motor shafts accurately using precision tools to minimize vibration and wear.

2️⃣Follow the manufacturer’s alignment guidelines to achieve proper fit.

7. Coupling Installation:

1️⃣Install the coupling between the pump and motor shafts, ensuring it fits properly and is aligned.

2️⃣Tighten coupling bolts to the recommended torque values.

8. Priming the Pump:

Fill the pump casing and suction piping with the pumping fluid, ensuring any trapped air is vented to prevent cavitation and ensure proper priming.

9. Startup:

1️⃣Gradually start the motor and monitor for any unusual vibrations or noises.

2️⃣Verify that the pump is operating within its designated performance parameters (flow rate, pressure, etc.).

10. Performance Testing:

1️⃣Conduct performance tests to verify the pump’s flow and head meet the specifications.

2️⃣Compare power consumption with the manufacturer’s data to ensure efficiency.

11. Safety Checks:

1️⃣Ensure all safety covers and guards are securely in place.

2️⃣Verify the functionality of safety devices such as pressure relief valves and temperature sensors.

12. Documentation:

Maintain detailed records of the installation, including alignment measurements, test results, and any adjustments made.

13. Training:

Provide operators with training on proper operation, maintenance, and troubleshooting procedures for the centrifugal pump.

14. Maintenance Schedule:

Establish a regular maintenance schedule that includes tasks such as lubrication, alignment checks, and vibration analysis to ensure long-term reliability.

✅This approach not only guarantees that the centrifugal pump performs optimally but also aligns with our commitment to providing sustainable and reliable water solutions.

#PumpInstallation #CentrifugalPumps

#WaterSolutions

#PumpMaintenance

#Efficiency

0 notes

Text

25+ years of solar power: investing in tomorrow ⚡ Your panels today, clean energy for decades! ☀️ Built to last, built to sustain—choose solar, choose the future. 🌱"

DC Submersible Motor Pumps | DC Monoblock Pumps | Controllers

Reach out for queries. 📱 +91 90310 02865 | 92644 33807 | 92644 33809 | 92644 33812 🌐https://royalsolarpump.com 📲http://wa.me/+919264474896

SolarPower #Sustainability #CleanEnergy #RoyalIndia #MakeInIndia #SustainableEnergy

0 notes

Text

Exploring the Jaguar F-Pace: The Ultimate Luxury SUV Experience

JAGUAR SHOWROOM IN BANGALORESHAKTI JAGUAR DEALERSHIP IN BANGALORECONTACT US

When it comes to luxury SUVs that seamlessly blend performance, style, and cutting-edge technology, the Jaguar F-Pace stands out as a true icon. As the first SUV from the British automaker, the F-Pace has redefined what it means to drive a premium vehicle, offering a perfect balance of sportiness, sophistication, and practicality. At Shakti Jaguar, we invite you to explore the unparalleled experience that the Jaguar F-Pace delivers.

Design: A Masterpiece of Elegance and Dynamism

The Jaguar F-Pace is a visual delight, combining sleek lines with a muscular stance that exudes confidence. Its bold grille, distinctive LED headlights, and sculpted bodywork reflect Jaguar's commitment to timeless design. The F-Pace’s aerodynamic profile not only enhances its aesthetic appeal but also improves efficiency and performance.

Step inside, and you’re greeted by a cabin that epitomizes luxury. Premium materials, including soft-touch leather, brushed aluminum, and sustainable wood veneers, create an ambiance of refined elegance. The spacious interior is designed with both driver and passengers in mind, offering ample legroom, advanced ergonomics, and customizable ambient lighting to set the perfect mood.

Performance: Thrilling Power and Precision

The Jaguar F-Pace is more than just a pretty face—it’s a performance powerhouse. With a range of engine options, including efficient Ingenium diesel and petrol engines, as well as the exhilarating P400 plug-in hybrid, the F-Pace caters to every driving preference. The P400 variant combines a 2.0-liter four-cylinder engine with an electric motor, delivering an impressive 398 horsepower and a pure-electric range of up to 33 miles, making it an excellent choice for eco-conscious drivers.

For those seeking adrenaline-pumping performance, the F-Pace SVR is the ultimate choice. Powered by a 5.0-liter supercharged V8 engine, it produces a staggering 550 horsepower, catapulting the SUV from 0 to 60 mph in just 4.3 seconds. Paired with Jaguar’s advanced all-wheel-drive system and adaptive dynamics, the F-Pace offers exceptional handling and stability, whether you’re navigating city streets or tackling winding mountain roads.

Technology: Innovation at Your Fingertips

The Jaguar F-Pace is packed with state-of-the-art technology designed to enhance your driving experience. The Pivi Pro infotainment system takes center stage, featuring a responsive 11.4-inch curved glass touchscreen with intuitive controls. With Apple CarPlay, Android Auto, and over-the-air software updates, you’re always connected and up to date.

The F-Pace also boasts a 12.3-inch Interactive Driver Display, which provides customizable information right in front of the driver. Advanced driver-assistance systems, such as adaptive cruise control, lane-keeping assist, and a 3D surround camera, ensure safety and convenience on every journey.

Comfort and Versatility: Designed for Life

The Jaguar F-Pace is as practical as it is luxurious. With a generous cargo capacity of up to 33.5 cubic feet (expandable to 69.1 cubic feet with the rear seats folded), it’s perfect for weekend getaways or daily errands. The optional Activity Key allows you to lock and unlock the vehicle without carrying your main key, ideal for outdoor adventures.

The F-Pace also prioritizes comfort, with features like heated and ventilated seats, a panoramic sunroof, and a Meridian sound system that delivers concert-quality audio. Whether you’re commuting to work or embarking on a cross-country road trip, the F-Pace ensures every journey is a pleasure.

Why Choose Shakti Jaguar?

At Shakti Jaguar, we are passionate about delivering an exceptional ownership experience. Our team of experts is dedicated to helping you find the perfect Jaguar F-Pace that suits your lifestyle and preferences. From personalized test drives to flexible financing options, we’re here to make your dream of owning a Jaguar a reality.

Conclusion

The Jaguar F-Pace is more than just an SUV—it’s a statement of sophistication, performance, and innovation. With its striking design, exhilarating performance, and cutting-edge technology, the F-Pace offers the ultimate luxury SUV experience. Visit Shakti Jaguar today to explore the Jaguar F-Pace and discover why it’s the perfect choice for discerning drivers.

0 notes

Text

How VFDs for 3 Phase Motors are Improving Precision in Industrial Automation

Industries like manufacturing, food processing, etc. often rely on machines to perform daily operations. One such key technology driving this precision is the Variable Frequency Drive (VFD). They enable better control, energy savings, and smoother operations. Let's dive into how VFD drives are making a difference and why they're becoming a must-have in modern automation.

What is a VFD for a 3-Phase Motor?

It is a device that controls the speed and torque of an electric motor by adjusting the frequency and voltage of the power supplied to it. Unlike traditional motor starters that simply turn motors on or off, a VFD for 3-phase motor allows for precise control over how fast or slow the motor runs.

The Magic of Precision Control

Like in a car without an accelerator- you have only two options: full speed or stop. But with a VFD drive, it's like having an accelerator pedal for your motor. You can control its speed depending on the task at hand.

For example, in a conveyor belt system, a variable frequency drive for 3-phase motor can adjust the speed of the belt to match the production rate. So, products can smoothly move without wasted energy. Also, in HVAC systems, VFDs can optimize fan speeds to maintain optimal airflow and temperature.

Soft Start: A Gentle Beginning

One of the standout features of a VFD for 3-phase motor is its ability to provide a soft start motor starter function. Traditional motors often start with a sudden jolt of power, which causes power surges, increasing energy costs and stressing the electrical system.

On the other hand, a soft start motor starter gradually enhances the motor's speed, along with reducing mechanical stress. It is useful in applications like pumps, compressors, and heavy machinery, where sudden starts can cause damage.

Saving Money and the Planet

Energy efficiency is a big deal in today's world, and VFD drives are leading the charge. By adjusting the motor's speed to match the load requirements, VFDs prevent energy wastage.

Industries that use variable frequency drives for 3-phase motors often see a noticeable drop in their energy bills. Over time, these savings can offset the initial cost of the VFD, which makes it a great investment.

Enhancing Automation with Smart Features

Modern VFDs for 3-phase motors come packed with advanced features that take industrial automation to the next level. Most variable frequency drives (VFDs) can be used together with sensors, PLCs and other automated systems. Such integration makes it possible to monitor and adjust the functions and processes as they happen.

A case in point is a packaging factory where a variable frequency drive is connected with sensors that measure the dimensions and the weight of the items so as to change the speed of the motor. Thus, this level of accuracy assures quality and minimizes wastage.

The Future of Industrial Automation

As industries continue to embrace automation, the demand for VFD drives is only going to grow. These are now indispensable in modern manufacturing. Whether it's a soft start motor starter function or the ability to fine-tune motor speeds, VFDs are proving to be a cornerstone of industrial innovation.

In conclusion, VFDs for 3-phase motors are more than just a piece of equipment—they're a tool for achieving greater precision, efficiency, and sustainability in industrial automation. So, when you invest in this technology, you are contributing to a greener future.

0 notes

Text

How the Siemens G120 Drive Enhances Industrial Automation

Industrial automation needs operations to work ever so efficiently and reliably because these are two primary factors which influence any process toward its successful accomplishment. This led Siemens, the world's largest supplier of automation and drive technology, to invent the SINAMICS G120 drive, one of the most advanced variable frequency drives-to really show how energy can be saved, systems improved, and basically the control of processes made easier across different industries.

What is the SINAMICS G120 Drive?

The SINAMICS G120 drive is somewhat of a modular frequency converter characteristic of good motor control, with balance on its energy efficiency versus its flexibility. This drive finds applicability in segments including manufacturing, automotive, food processing, and chemical plants. It can cater to ever-simple to much-complicated applications.

The modular design thus enables the user to configure the G120 drive flexibly, either by choosing different power modules or control units for its application. This design feature is further beneficial in terms of being able to repair and service the G120 drive, contributing to limiting downtime and minimizing costs associated with maintenance.

Some Features of the Siemens G120 Drive

1. Modular Design: The modular architecture of the Siemens G120 drive separates the control unit from the power module and allows great flexibility for customization. Separation of the two components allows independent component replacement and hence minimizes maintenance downtime and costs.

2. Excellent Safety Features: Safety is of the utmost importance in industrial practice. The G120 drive features integrated safety functions, including Safe Torque Off (STO) and Safe Stop (SS1), which provide a comfortable level of safety with minimal use of additional hardware.

3. High Energy Efficiency: When it comes to reducing operational expenses, energy efficiency is of prime interest to various businesses. Features such as regenerative feedback contribute to energy efficiency while helping SINAMICS G120 drives minimize their carbon footprint and aid their sustainability drive.

4. Comprehensive Communication: The Siemens G120 drive supports a comprehensive array of communication protocols—PROFINET, PROFIBUS, and Modbus—to allow truly seamless integration into existing automation systems. This makes connection enhanced and allows for real-time data monitoring to improve system performance.

5. Straightforward Operation and Commissioning: The drive is equipped with a user-friendly interface, including easy parameterization, which provides quick configuration and simple operation. The commissioning process has been greatly simplified with SINAMICS Startdrive software to enable quick setup and parameter changes.

Applications of SINAMICS G120 Drive

The application areas of the G120 drive are highly flexible and varied:

Pumps and Fans – Speed control optimization and energy saving.

Conveyance and Material Handling – Smooth acceleration and deceleration allow precise control.

Machine Tools – Improves the precision with which cutting, drilling, and milling operations are done.

HVAC – Controls all air conditioning and ventilation units much better.

Textile and Paper Industry- Motion control with precision enhances the performances of various production lines.

Reasons to Choose Siemens G120 Drive

For outstanding performance, flexibility, and reliability, the Siemens G120 drive is preferred by industries around the globe. Here are some distinguishing features of this drive:

Build tough and ready for the worst industrial environments.

Easy integration within Siemens automation systems.

Technically advanced, ready for the 4th Industrial revolution.

Global support by Siemens service and maintenance.

Conclusion

The SINAMICS G120 drive is, in fact, an advanced solution for industries in pursuit of energy-saving motion control technology, effective technology, and reliability. For these reasons, its modular design, safety features, and interconnectivity have made it the choice of many industries wanting to optimize their automation processes. Whether in manufacturing, material handling, or HVAC applications, the G120 drive by Naksh Technology Solutions LLP boasts high performance and operational efficiency.

0 notes

Text

How Does Energy Efficient Spa Provide Luxury and Sustainability?

When it comes to investing in a hot tub, you must prioritize your comfort and relaxation. But energy efficiency is now a top priority for those who are concerned about the environment. Northern Lights Hybrid Spa combines cutting-edge technology with smart design to deliver unparalleled performance while drastically reducing energy consumption.

Please take a closer look at what makes this spa the ultimate choice for those who value efficiency, sustainability, and high-end features:

Unmatched Insulation

The spa is manufactured with advanced insulating technologies, starting with a spray foam core shell that offers exceptional thermal retention. In addition, the 1-inch cavity insulation, combined with infrared heat-reflecting sheeting, offers minimal heat loss.

To further boost energy efficiency, the spa features a 3-inch insulated mounting base and a 5-inch insulated cover. These components combine together to reduce standby heat loss significantly, keeping energy use to a minimum even when the spa isn’t in active use.

State-of-the-Art Spa Heat Pump

This spa features an energy-efficient heat pump that reduces power consumption by up to 70-80% compared to traditional heating systems. Using advanced technology, it seamlessly integrates with the spa’s superior insulation, ensuring a luxurious and cost-effective experience.

Energy-Efficient Pump Technology

The LX ultra-quiet pump is another significant feature of this energy-efficient spa. It features a 2-pole/6-pole motor design which ensures ultra-low energy consumption while drawing less than 0.4 amps during circulation. This system ensures energy savings of up to two-thirds over standard pumps, without compromising performance.

The LX Defender Series pump reduces operational temperature, saves energy, and extends the pump’s lifespan. Its ultra-quiet operation offers a peaceful spa experience, while the durable build guarantees long-term reliability.

Eco-Friendly Design

Apart from energy efficiency, this spa system has innovative features to enhance convenience and comfort. Standard ozone and ionization systems provide clean and hygienic water, while LED lighting and Wi-Fi controls offer modern functionality at your convenience. Despite these luxurious additions, the spa is perfectly engineered to minimize its environmental footprint.

Why Invest in an Energy-Efficient Hot Tub?

Investing in an energy-efficient hot tub helps reduce operating costs and allows you to embrace sustainable luxury. With features like reduced power consumption, noiseless operation, and extended equipment lifespan, this spa showcases the advancement in wellness technology.

Experience the perfect balance of relaxation and responsibility with the Northern Lights Hybrid Spa available at Northern Lights Polar Hot Tubs. Manufactured with innovation, sustainability, and superior craftsmanship, this spa truly showcases the standard for modern hot tubs. For more information about our hot tub systems, please contact us today at 1-800-759-8990.

0 notes

Text

Who Is The Best Effluent Treatment Plant Manufacturer In Noida ?

Effective treatment of effluent waste & wastewater is now more & more significant than ever in the advanced crowded world as cities keeps on bulging in its number along with urban development on rise. If effluent is not handled, there can be major risks to the environment & public health. Effluent treatment Plant systems are essential in this situation. One water treatment business such as Commercial RO Plant that in particular sticks out as the only leading manufacturer of ETP plants in Noida.

Effluent treatment plants are specialist facilities built to clean wastewater of impurities & prepare it for reutilization or disposal. These facilities implement a variety of techniques, such as physical, chemical, & biological treatments, to filter out organic waste, solid waste, & other contaminants from the effluent. After treatment, the water is either dumped into bodies of water or utilized for non-potable purposes like industrial operations or irrigation.

Consequences or Costs of Not Taking Effluent Treatment Facilities in Utilization for Treating wastewater

There would be dire negative effects if Noida were to lose its supply of effluent treatment plant manufacturers. Unprocessed effluent would seep straight into bodies of water, polluting them with dangerous materials & putting human wellbeing & aquatic lifecycle at serious threat that can result in many bigger hazards. Not only would the unprocessed effluent waste disposed out of the city with filthy & bad smell, rather it might also cause a detrimental effect on tourism & economy.

The Top Currently Existing Effluent Treatment Plant Manufacturer in Noida is Commercial RO Plant working Under it’s core company Netsol Water

Owing to its cutting-edge trending technology, unwavering commitment to maintain their quality, along with offering outstanding services to the customers, Commercial RO Plant has a remarkable journey & has solidified its brand name as the leading top producer of effluent treatment plant in Noida.

The Effluent Treatment Plants made by Commercial RO Plant Have Particular Features:

Innovative Therapeutic Methods for Rigorous effluent Treatment

Using treatment processes, Commercial RO Plant ensures that the treated water meets or exceeds all regulatory criteria. Their factories incorporate modern facilities & technologies, such as membrane bioreactors, UV disinfection, as well as tertiary treatment systems, to guarantee maximum efficiency along with efficacy.

Tailor-Made Resolutions offered to every ETP Plant Type

Since each customer has unique needs, Commercial RO Plant offers effluent treatment plant solutions that are adaptable & uniquely designed to meet those needs. Their team of experts works closely with clients to plan & carry out systems that meet their specific needs, whether the assignment is for an industrial site, residential complex, or municipal treatment facility.

Complete Efficiency in the Consumption of energy Supplied

Energy efficiency is given top priority in the designs of Commercial RO Plant's ETP plants, which include cutting-edge progressive technology to decrease energy usage & save operating costs. Specified factories incorporates these treatment plants which involves aeration systems with high power efficient motors, & pumps that makes the operation very efficient, running industries more sustainably & with concerns of the environment.

Strength, Durability, & Dependability

Commercial RO Plant's Effluent treating plants are long-lasting due to their thorough attention to every detail mentioned by clients & their utilization of premium materials in the manufacturing units. In the very long run for the future, their durable designs saves & offers clients more time & money while minimizing maintenance needs & downtime & guaranteeing dependable functioning.

Significant Benefits of the Effluent Treatment Plants by Commercial RO Plant as the most proficient Effluent Treatment Plant Manufacturer in Noida

Adherence to environmental standards

The effluent treatment facilities with diverse manufacturing unitsoperated by Commercial RO Plant are built to meet or beyond all applicable environmental standards, guaranteeing the safety of the treated water for release or repurposing. Clients benefit from this dedication to environmental compliance by avoiding exorbitant penalties & legal problems.

Very Economical for Value of Money

Commercial RO Plant's effluent treatment facilities provide long-term cost reductions through the integration of energy-efficient technology & robust construction. The decreased energy usage & fewer maintenance needs result in lower operating expenses for customers.

Thorough Examination & Evaluation has led to the 100% Smell & Odour Management

Commercial RO Plant acknowledges the need to manage odors in effluent treatment facilities. Modern odor control systems employed in their companies guarantee that offensive odors are minimized, enhancing the quality of life for the area's residents.

Well-trained & Informative Knowledgeable Crew

A group of incredibly talented & seasoned individuals at Commercial RO Plant are committed to providing top-notch customer service. Their staffs make sure that clients receive the greatest solutions & assistance available at every stage of the process, from design & installation to continuing maintenance & support.

Conclusion

It is entirely justified that Commercial RO Plant along with many of its supporting companies is the biggest effluent treatment plant Manufacturer in Noida. They stand out from the competition because of their dedication to quality, innovation, & client happiness. Customers who choose Commercial RO Plant may feel secure in the knowledge that they are investing in a effluent treatment plant system that will meet their needs for many years to come which can be the one that is dependable, effective, & environmentally friendly.

#effluent treatment plant#effluent treatment plant manufacturer in noida#netsol water#save water#water is life#water treatment plant

0 notes